impact punch down tool что это такое

Забивка кабелей – специальные инструменты

Кроссировщик, прибор для расшивки (punch down tool), забивка кабеля – все это специализированный инструмент для заделки витой пары в коннекторы, а также в коммутационные панели. Для обывателей, не посвященных в тонкости структурированной кабельной системы, может быть неясен сам термин «забивка». Так вот, под этим понятием подразумевается процесс, при котором кабельные проводники помещаются в определенной последовательности между контактами панели либо модуля.

Для чего нужна заделка?

От выбранного инструмента для монтажа напрямую зависит качество и быстрота монтажных работ, связанных с формированием СКС. Именно поэтому рекомендуется использовать профессиональный инструмент для выполнения той или иной задачи.

Как может показаться на первый взгляд, в заделке проводов абсолютно нет ничего, что могло бы вызвать определенные трудности, однако это не совсем так. В действительности существует масса нюансов и деталей, которые следует учитывать при расшивке витой пары. В связи с этим существует даже несколько видов инструмента для кроссировки сетевого кабеля. Они различаются между собой в зависимости от конструкционного исполнения:

Кроссировщики могут также отличаться по типу ножей:

Бюджетные модели punch down tool подойдет для тех, кто не занимается прокладкой локальных сетей постоянно, если же это является вашей специализацией, лучше обратить внимание на более профессиональные приборы.

Универсальные наборы для заделки

Системным администраторам, выполняющим ремонтно-монтажные работы, как нельзя кстати придется

К тому же, в зависимости от стоимости такого набора, могут прилагаться разнообразные коннекторы, сменные ножи для кроссировщика. От цены будет зависеть и сама упаковка: она может представлять собой удобный чемоданчик, в котором удачно разместится весь инструмент.

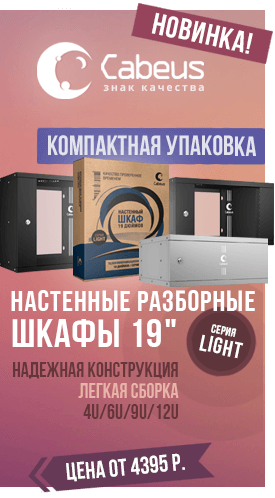

Среди предлагаемых различными фирмами комплектов наиболее выгодно выделяется продукция Cabeus. Она завоевала доверие потребителей по всему миру благодаря великолепному соотношению цены и качества. По этой торговой маркой выпускаются наборы и для витой пары, и для коаксиальных линий, и для волоконно-оптических проводников. Приобретая целый набор инструментов, можно существенно сэкономить, поскольку отдельная покупка приспособлений, входящих в комплект, обойдется значительно дороже.

Если стоит выбор, где купить инструмент для заделки, выбирайте надёжного производителя. Компания « АнЛан » занимает лидирующие позиции на рынке РФ с 2007 года. Разумная цена и европейское качество — то, что отличает продукцию компании от других организаций.

Punch Down Tools for Network Cabling

Sheldon

A punch down tool, also referred to as krone tool, is a small but primary tool for network technicians to install wiring for telephone, computer and various audio networks. It is widely used to terminate the Ethernet cables by inserting the cables wires into the insulation-displacement connectors (IDC) on the punch down blocks, patch panels, keystone modules, and surface mount of boxes. It works by inserting the wire for a corrosion resistant termination and then trims off excess wire, which ensures fast and precise connections with less effort.

Common Features of Punch Down Tool

The most common punch down tools available on the market include standard impact tool, universal automatic impact tool and corrosion resistant termination tool. A typical punch down tool consists of a handle, an internal spring mechanism, and a removable slotted blade. Punch down tools are typically 6-8 inches long with a blade at one end. The top and bottom of the tools are usually with different colors to help users identify which side is used to cut the wire. Most models have a changeable blade and a pressure adjustment screw or knob.

The dimensions of the punch down tool are not standardized. Some tools have dimensions of 5.35 in x 1.06 in x 1.06 in. Others have 5.25 in x 1.26 in x 1.26 in, 7.00 in x 2.02 in x 2.02 in and so on. Their weights also vary with their sizes. Whatever the dimensions of the punch down tool are, the usage is the same.

Blade types of Punch Down Tool

To accommodate various connector types, punch down tools have different types of blades with 66 blade or 110 blade. Different blades are used depending on whether you are terminating 66-block or 110-block which will be explained below.

66 Punch Down Block

The 66 block is a type of punch down block used to connect sets of wires in a telephone system. They have been manufactured in three sizes, A, B and M. A and B have six clips in each row while M has only 4. Each row of a 66 block is set up for one pair of wires to be spliced to another pair. however, any pair of clips can be used to connect any two wires.

The A blocks spaced the rows further apart and has been obsolete for many years. The B style is used mainly in distribution panels were several destinations (often 1A2 key telephones) need to connect to the same source. The M blocks are often used to connect a single instrument to such a distribution block. 66 blocks are designed to terminate 22 through 26 AWG solid copper wire. 66 blocks are available pre-assembled with an RJ-21 female connector that accepts a quick connection to a 25-pair cable with a male end. These connections are made between the block and the customer premises equipment (CPE).

110 Punch Down Block

As an updated version of 66 block, 110 punch down block is the core part of the connection management system, used to connect wiring for telephone systems, data network wiring, and other low-voltage wiring applications. 110 type wiring block is flame retardant, injection-molded plastic to do the basic devices and the termination cabling system is connecting on it.

The 110 block is designed for 22 through 26 gauge solid wire. This is the termination used on cat5e patch panel, cat 6 patch panel and RJ-45 jacks. They are also formed into block type terminations the size of small 66 blocks. The 110 block is designed for 500 MHz (1 gb/s) or greater bandwidth. 110 blocks are acceptable for use with AES/EBU digital audio at sample rates greater than 268 KHz as well as gigabit networks and analog audio. 110 type wiring block system uses easy quick-fit plug-hop loops which can be simply rearranged, so it provides a convenient cross-connect to non-professional and technical personnel management system.

How to Use a Punch Down Tool

When it comes to repair or install Ethernet cable, you’ll inevitably need to cut and position wires. Exposed wires can be dangerous and may cause your connections broken. Punch down tool thus is necessary to ensure that your wires are secure, and meanwhile to help trim and contain the wires in a basic jack. Then how to use a punch down tool? Just follow the following steps.

Step One: Strip back the cable jacket

What should be noticed is that always leave about 2.5 inches (6 cm) at the end of the cable. Insert the cable into the cable stripping tool or modular crimping tool, and spin it around a few times. Then remove the jacket.

Step Two: Expose the wires

After removing the cable jacket, you will have a few inches of exposed cable. Then gently pull away the wire pairs from the center of the cable so they fan out. Separate the wire pairs by twisting in a counterclockwise motion. Try to straighten the ends as much as you can in order to make them easier to terminate.

Step Three: Place the cable wires in the jack

Take the protective cover off the top of the jack and set the cable into the block of the jack. Insert each wire into its own separate slot, making sure that the wire matches the A or B configuration. The conductor wires should be extending out of the jack.

Note: Consider to choose between T568A or T568B wiring scheme. The T568B is becoming more popular since it can be used with older color codes as well as newer codes.

Step Four: Terminate the conductor wires

Take your punch down tool and press it down on the conductor wires to cut them. The angled part of the blade should contact with the long sturdy side of the jack. This will also make sure the wires that are cut are flush with the jack.

Step Five: Inspect the wires

Check each wire to make sure there is no overhang out the side of the jack. You should also make sure that the edge of the cable jacket is near the base of the jack and the wires you just terminated. The wires should be securely in place. If you notice wires sticking out the side, take a wire cutter and carefully trim the wire so that it’s flush with the jack.

Step Six: Place a dust cap on the jack.

Snap the dust caps in place to protect the wires. This will keep the connection secure and can prevent strain on the wires. The dust cap is also very easy to remove: simply pop off the dust cap using a flat-head screwdriver inserted into the indentation on the side.

Note: Fail to set the dust caps back on the jack indicates that your wires may not be seated correctly. It is better to check the wires again and make sure they are secure and trimmed.

Introducing: trueIMPACT 110 Punch Down Tool

Written by Don Schultz, Technical Sales Representative and Fluke Networks Certified Technician

How can trueCABLE redefine the simple ho-hum punch down tool?

Well, you start by asking an actual installer what they want! Namely:

What is a kinetic energy punch down tool. really?

Impact punch down tools are used to terminate wires into punch down patch panels and punch down keystone jacks.

The idea is the tool head blade is used to push a wire conductor into a IDC terminal slot (Insulation Displacement Conductor). At a certain set point the mechanism is triggered and an internal spring uses kinetic force to shove the conductor down between the metal prong contacts to make an electrical connection. Oftentimes, the blade will also flush cut the conductor at the end of the process.

The tool head blades come in four styles:

Each of those blade styles handles different types of wire and terminals. Most often, you see the 110 type and Krone type that is by far the most common for Category 5e and above Ethernet terminations. Secondarily, 66 is next most commonly used for Cat3 (voice/telephone) punch down blocks for. BIX is rarely seen in the USA.

This blog will focus on our trueIMPACT 110 Impact punch down tool.

There is a short video demonstration of the trueIMPACT tool below. We recommend you watch the video and read this blog as both mediums bring something to the table.

Our trueIMPACT 110 tool:

Tool walk around

The spudger and hook tools shown to good effect. LO and HI force adjustment with tool head release dial

Double ended 110 tool head. The design is standard “twist and lock” and is compatible with any “twist and lock” tool head for sale on the open market. One end has the flush cut blade. it is sharp so be careful!

Punching down a keystone jack

Final thoughts…

Our 110 impact tool requires no maintenance at all. There are no user serviceable parts and it should never be oiled. After using your tool, it is a great idea to store the tool head in the hollow handle to avoid accidental injury.

We hope you find this tool to be more useful than any other similar tool you have used up to this point. We would love to show off your photos of it in use with your permission.

How to use a punch down tool

Network performance and reliability are the foundation of a robust and sound communication system. Therefore, to ensure a successful connection between the computers and the data center, network technicians need the right assistance tools, punch down tool among which, is extremely essential for the smooth networks running. So, in this article, we will offer you some tips on how to use punch down tool effectively.

Punch Down Tool Description

Also referred to as krone tool, the punch down tool is a small hand tool most often used by telecom and data network technicians to install wiring for telephone, computer and various audio networks. This tool allows for the quick and effective cross-connection of wires through the use of 66-type or 110-type connection blocks.

Punch down tool is commonly used for the termination works in the copper network. It is used to terminate the Ethernet cables (Cat5/5e/6/6a) by inserting the cables wires into the insulation-displacement connectors (IDC) on the punch down blocks, patch panels, keystone modules, and the surface mount of boxes. The name is thus derived from the method by which the tool pushes a solid copper wire between metal blades on the connection block, and cuts off the excess by punching the tool, driving the tool blade through the wire.

How to Use Punch Down Tool

When there comes the need to repair or install cables, you’ll inevitably need to cut and secure wires. However, exposed wiring can be dangerous and may cause your connections to short out. Punch down tool thus is necessary to ensure that your wires are secure, and meanwhile to help trim and contain the wires in a basic jack. Then how to use the punch down tool? Here we offer you a guide for reference.

What should be noticed is that always leave about 2.5 inches (6 cm) at the end of the cable. Insert the cable into the cable stripping tool or modular crimping tool, and spin it around a few times. Then remove the jacket. Stripping back the cable will help you remove the jacket to expose enough of the cable, so you can separate it.

After removing the cable jacket, you will have a few inches of exposed cable. Then gently pull away from the wire pairs from the center of the cable so they fan out. Separate the wire pairs by twisting in a counterclockwise motion. Try to straighten the ends as much as you can, and this can make them easier to terminate.

Take the protective cover off the top of the jack and set the cable into the block of the jack. Insert each wire into its own separate slot, making sure that the wire matches the A or B configuration. The conductor wires should be extending out of the jack.

Note: Consider to choose between T568A or T568B wiring scheme. The T568B is becoming more popular since it can be used with older color codes as well as newer codes.

Take your punch down tool and press it down on the conductor wires to cut them. The angled (cut) part of the blade should contact with the long sturdy side of the jack. This will also make sure the wires that are cut are flush with the jack.

Look at each wire to make sure there is no overhang out the side of the jack. You should also make sure that the edge of the cable jacket is near the base of the jack and the wires you just terminated. The wires should be securely in place. If you notice wires sticking out the side, take a wire cutter and carefully trim the wire so that it’s flush with the jack.

Snap the dust caps in place to protect the wires. This will keep the connection secure and can prevent strain on the wires. The dust cap is also very easy to remove: simply pop off the dust cap using a flat-head screwdriver inserted into the indentation on the side.

Note: Fail to set the dust caps back on the jack indicates that your wires may not be seated correctly. It is better to check the wires again and make sure they are secure and trim.

A punch down tool, also referred to as krone tool, is a small but primary tool for network technicians to install wiring for telephone, computer and various audio networks. It is widely used to terminate the Ethernet cables by inserting the cables wires into the insulation-displacement connectors (IDC) on the punch down blocks, patch panels, keystone modules, and surface mount of boxes. It works by inserting the wire for a corrosion resistant termination and then trims off excess wire, which ensures fast and precise connections with less effort.

Common Features of Punch Down Tool

The most common punch down tools available on the market include standard impact tool, universal automatic impact tool and corrosion resistant termination tool. A typical punch down tool consists of a handle, an internal spring mechanism, and a removable slotted blade. Punch down tools are typically 6-8 inches long with a blade at one end. The top and bottom of the tools are usually with different colors to help users identify which side is used to cut the wire. Most models have a changeable blade and a pressure adjustment screw or knob.

The dimensions of the punch down tool are not standardized. Some tools have dimensions of 5.35 in x 1.06 in x 1.06 in. Others have 5.25 in x 1.26 in x 1.26 in, 7.00 in x 2.02 in x 2.02 in and so on. Their weights also vary with their sizes. Whatever the dimensions of the punch down tool are, the usage is the same.

Blade types of Punch Down Tool

To accommodate various connector types, punch down tools have different types of blades with 66 blade or 110 blade. Different blades are used depending on whether you are terminating 66-block or 110-block which will be explained below.

66 Punch Down Block

The 66 block is a type of punch down block used to connect sets of wires in a telephone system. They have been manufactured in three sizes, A, B and M. A and B have six clips in each row while M has only 4. Each row of a 66 block is set up for one pair of wires to be spliced to another pair. however, any pair of clips can be used to connect any two wires.

The A blocks spaced the rows further apart and has been obsolete for many years. The B style is used mainly in distribution panels were several destinations (often 1A2 key telephones) need to connect to the same source. The M blocks are often used to connect a single instrument to such a distribution block. 66 blocks are designed to terminate 22 through 26 AWG solid copper wire. 66 blocks are available pre-assembled with an RJ-21 female connector that accepts a quick connection to a 25-pair cable with a male end. These connections are made between the block and the customer premises equipment (CPE).

110 Punch Down Block

As an updated version of 66 block, 110 punch down block is the core part of the connection management system, used to connect wiring for telephone systems, data network wiring, and other low-voltage wiring applications. 110 type wiring block is flame retardant, injection-molded plastic to do the basic devices and the termination cabling system is connecting on it.

The 110 block is designed for 22 through 26 gauge solid wire. This is the termination used on cat5e patch panel, cat 6 patch panel and RJ-45 jacks. They are also formed into block type terminations the size of small 66 blocks. The 110 block is designed for 500 MHz (1 gb/s) or greater bandwidth. 110 blocks are acceptable for use with AES/EBU digital audio at sample rates greater than 268 KHz as well as gigabit networks and analog audio. 110 type wiring block system uses easy quick-fit plug-hop loops which can be simply rearranged, so it provides a convenient cross-connect to non-professional and technical personnel management system.

How to Use a Punch Down Tool

When it comes to repair or install Ethernet cable, you’ll inevitably need to cut and position wires. Exposed wires can be dangerous and may cause your connections broken. Punch down tool thus is necessary to ensure that your wires are secure, and meanwhile to help trim and contain the wires in a basic jack. Then how to use a punch down tool? Just follow the following steps.

Step One: Strip back the cable jacket

What should be noticed is that always leave about 2.5 inches (6 cm) at the end of the cable. Insert the cable into the cable stripping tool or modular crimping tool, and spin it around a few times. Then remove the jacket.

Step Two: Expose the wires

After removing the cable jacket, you will have a few inches of exposed cable. Then gently pull away the wire pairs from the center of the cable so they fan out. Separate the wire pairs by twisting in a counterclockwise motion. Try to straighten the ends as much as you can in order to make them easier to terminate.

Step Three: Place the cable wires in the jack

Take the protective cover off the top of the jack and set the cable into the block of the jack. Insert each wire into its own separate slot, making sure that the wire matches the A or B configuration. The conductor wires should be extending out of the jack.

Note: Consider to choose between T568A or T568B wiring scheme. The T568B is becoming more popular since it can be used with older color codes as well as newer codes.

Step Four: Terminate the conductor wires

Take your punch down tool and press it down on the conductor wires to cut them. The angled part of the blade should contact with the long sturdy side of the jack. This will also make sure the wires that are cut are flush with the jack.

Step Five: Inspect the wires

Check each wire to make sure there is no overhang out the side of the jack. You should also make sure that the edge of the cable jacket is near the base of the jack and the wires you just terminated. The wires should be securely in place. If you notice wires sticking out the side, take a wire cutter and carefully trim the wire so that it’s flush with the jack.

Step Six: Place a dust cap on the jack.

Snap the dust caps in place to protect the wires. This will keep the connection secure and can prevent strain on the wires. The dust cap is also very easy to remove: simply pop off the dust cap using a flat-head screwdriver inserted into the indentation on the side.

Note: Fail to set the dust caps back on the jack indicates that your wires may not be seated correctly. It is better to check the wires again and make sure they are secure and trimmed.

A punch down tool is commonly used by data network and telecom technicians in installing wiring in computers, phones, and audio networks. This tool can allow you to cross-connect wires quickly and efficiently using 110-type or 66-type connection blocks. This article will teach you how to use this tool correctly and safely.

Things you will need

1) Safety glasses

2) Telecom wire or copper networking

3) 66- or 110-type connection block

Guide and tips to using a punch down tool

1) Acquaint yourself with features of the punchdown tool Even though, there are a lot of punch down tool manufacturers and models, most are generally six to eight inches in length with a blade at one end. The tool’s bottom and top sections are coloured differently so that users can easily know which side is for cutting wires. The majority of punch down tool models come with a pressure adjustment knob or screw and a changeable blade.

2) Get ready to punch down a wire As you stand in front of the connection block, grip the punch down tool using one hand, making sure that the cutting blade is facing down. Using your other hand, hold the wire down and then, coil it through the connection block terminal that you have selected.

3) Punching the wire down While holding the wire’s end firmly, put the punch down tool’s blade on the connection terminal that you have chosen and press forward until you are able to reach the terminal’s bottom. As you continue to hold the wire’s end, firmly punch the tool using a straight-forward motion. If this is done right, any excess wire would be cleanly cut off and the remaining wire would be easily connected to the terminal.

4) Checking your connection See to it that the connection is secure and that there’s no broken or loose wire that is left in the connection block. Pull the wire to test if it is indeed fastened securely to the right terminal. Tips 1) When using punch down tools, always wear safety goggles or glasses. 2) Do not use a punch down tool to tighten up flat head screws as this can break or shatter the blade. 3) Though most models are made of plastic, punch down tools can still conduct current. Keep this in mind when working with electrical circuits.

Punching-down a cat cable into a patch panel may seem like tricky business, but once you’ve got the basics down it becomes as easy as the proverbial pie. This high-level guide is here to help.

What You’ll Need

Step 1: Prepare the Cat Cable

Ideally you should remove approximately 1 inch (25mm) of the outer jacket, this ensures a nice clean fit into the patch panel without the risk of exposing too much cable and damaging it. Once the outer jacket has been removed you will notice 4 pairs of copper cables, making up a total of 8 cables. In order to successfully punch down the cables into the patch panel you will need to gently untwist the pairs so that the 8 cables can be individually worked work with.

Step 2: Prepare the Patch Panel

Take the screwdriver and begin by unscrewing the section of the panel you are going to work with and place the remainder to the side. While doing so take note of the label on the inside of the panel with the color code printed on to it. This will be explained in the next step

Step 3: Put Cat Cable into Patch Panel

First off you will notice that there are in fact 2 pin-out types, these are typically labelled A and B respectively. Generally most installations would use pin-out B, but please be sure to check which one is right for your specific application.

Once you have selected a pin-out type you will see that each one has it’s own color code, with 4 solid colors and 4 stripes. Simply match the solid colored wires to the solid color slots and do the same with the stripes. Inserting the wires into the slots requires nothing more than gently pushing them in. Once all the wires have been correctly inserted it is time to being with the actual punching down.

Step 4: Punching Down

Once you have selected a pin-out type you will see that each one has it’s own color code, with 4 solid colors and 4 stripes. Simply match the solid colored wires to the solid color slots and do the same with the stripes. Inserting the wires into the slots requires nothing more than gently pushing them in. Once all the wires have been correctly inserted it is time to being with the actual punching down.

In order to correctly punch down the wires into the patch panel you will need to make use of a Punch Down Tool. The tool itself is fairly simple in that it has a pointed side and a flat size. The pointed side is the side that will trim the ends of the wires to leave a clean cut.

Begin by positioning the tool over the wire you intend to punch down and then using as much force as required push down on the handle of the tool. This will both push the wire firmly into place and trim the ends at the same time., continue doing this for all the remaining wires. You may also notice that occasionally some of the wire ends remain, you can usually fix this by gently removing them by hand as the tool may not have cleaved all the way through the wires on the initial punch down.

Want to watch it done? Check out the video below for a short tutorial which outlines most of what we have discussed in this guide.

Network performance and reliability are the foundation of a robust and sound communication system. Therefore, to ensure a successful connection between the computers and the data center, network technicians need the right assistance tools, punch down tool among which, is extremely essential for the smooth networks running. So, in this article we will offer you some tips on how to use punch down tools effectively.

Also referred to as krone tool, the punch down tool is a small hand tool most often used by telecom and data network technicians to install wiring for telephone, computer and various audio networks. This tool allows for the quick and effective cross-connection of wires through the use of 66-type or 110-type connection blocks.

Punch down tool is commonly used for the termination works in the copper network. It is used to terminate the Ethernet cables (Cat5/5e/6/6a) by inserting the cables wires into the insulation-displacement connectors (IDC) on the punch down blocks, patch panels, keystone modules, and surface mount of boxes. The name is thus derived from the method by which the tool pushes a solid copper wire between metal blades on the connection block, and cuts off the excess by punching the tool, driving the tool blade through the wire.

When there comes the need to repair or install cables, you’ll inevitably need to cut and secure wires. However, exposed wired can be dangerous and may cause your connections to short out. Punch down tool thus is necessary to ensure that your wires are secure, and meanwhile to help trim and contain the wires in a basic jack. Then how to use the punch down tool? Here we offer you a guide for reference.

What should be noticed is that always leave about 2.5 inches (6 cm) at the end of the cable. Insert the cable into the cable stripping tool or modular crimping tool, and spin it around a few times. Then remove the jacket. Stripping back the cable will help you remove the jacket to expose enough of the cable, so you can separate it.

After removing the cable jacket, you will have a few inches of exposed cable. Then gently pull away the wire pairs from the center of the cable so they fan out. Separate the wire pairs by twisting in a counterclockwise motion. Try to straighten the ends as much as you can, and this can make them easier to terminate.

Take the protective cover off the top of the jack and set the cable into the block of the jack. Insert each wire into its own separate slot, making sure that the wire matches the A or B configuration. The conductor wires should be extending out of the jack.

Note: Consider to choose between T568A or T568B wiring scheme. The T568B is becoming more popular since it can be used with older color codes as well as newer codes.

Take your punch down tool and press it down on the conductor wires to cut them. The angled (cut) part of the blade should contact with the long sturdy side of the jack. This will also make sure the wires that are cut are flush with the jack.

Look at each wire to make sure there is no overhang out the side of the jack. You should also make sure that the edge of the cable jacket is near the base of the jack and the wires you just terminated. The wires should be securely in place. If you notice wires sticking out the side, take a wire cutter and carefully trim the wire so that it’s flush with the jack.

Snap the dust caps in place to protect the wires. This will keep the connection secure and can prevent strain on the wires. The dust cap is also very easy to remove: simply pop off the dust cap using a flat-head screwdriver inserted into the indentation on the side.

Note: Fail to set the dust caps back on the jack indicates that your wires may not be seated correctly. It is better to check the wires again and make sure they are secure and trimmed.

Fiber cabling solutions for data center

Punch down tool, sometimes called krone tool, is a small hand tool that technicians often use to connect telecommunication or network wires to punch down block, patch panels, keystone module and surface mount boxes. It usually comprises a handle, a spring mechanism and a removable slotted blade that can cut off excess wires. Having a dependable punch down tool can help you save time when installing cables, for it allows quick and effective cross-connection of wires. This article aims to introduce how to operate and choose a right punch down tool in cabling projects.

It’s common to cut down or secure wires when technicians are installing cables. In order to ensure the wires are secure, it’s essential to use a punch down tool to trim and contain them in a basic jack. Then how to use a punch down tool? Take punching down a jack for example.

Step one. Strip back the cable jacket. Put the cable into a striping tool and spin it around a few times. Remove the jacket after making sure the jacket is out. Then gently pull away the wire pairs from the center of the wires to make them fan out. Try to strengthen the ends so that you can make them easier to terminate later.

Step two. Put the wires in the jack. Get rid of the protective cover of the jack and put the cable into the block of the jack. Then insert each branch of the wires into its own separate slot, making sure that the wire matches the A or B configuration.

Step three. Terminate the conductor wires. Press the punch down tool on the conductor wires to cut them. Make sure the cut part of the blade comes into contact with the long sturdy side of the jack, which will ensure the wires to be cut are flush with the jack. In this process, try to punch straight down to prevent the jack from bending. Once you heard a loud click, it means you have terminated the wire correctly.

Step four. Check out the wires. Having finished the termination, do not forget to inspect it. Try to look at each wire to make sure there is no overhang out the side of the jack. Once ensuring the termination is finished successfully, remember to snap a dust cap in place so that the wires are protected.

If you have experience of terminating cables like Cat5e, Cat6 or Cat6a which are needed to connect with keystone jacks, you may know clearly how important it is to have a suitable punch down tool at your side when installing cables. If you want to make your installation work faster and easier, the following considerations may help you.

Improve speed. In order to finish work faster, the first factor to consider is speed. As we have mentioned above, technicians must first strip the outer jacket and put the wire in the right slots during the punch down process. Therefore, a good punch down tool needs to help technicians finish the procedure quickly.

Increase accuracy. This is another factor technicians need to consider. You can image that if a technician has to terminate more than one hundred wires, how can he ensure that no mistake occurs all the time? Improper termination can result in network downtime and waste technicians’ time and resources. So whether a punch down tool can help workers increase accuracy or not should be taken into consideration.

Reduce fatigue. After working for a long time, tiredness cannot be avoided. Reducing hand fatigue is a critical factor in wire terminations, especially for technicians who will work in large job sites. Because small mistakes may lead to lots of sources wasted.

Usability. Good punch down tools should have features such as easy-to-use handles and easy for operations, which allow for high usability across a wide range of settings and requirements.

Punch down tools are a necessary part in cable installations. A decent tool can make the work of technicians easier when installing and maintaining cable, and it also can help operators save money. In a word, it’s beneficial to choose a suitable punch down tool.

110 punch down block is also referred to as cross-connect block, terminating block, or a connecting block for network cables. It is a tool that connects one group of wires to another group of wires through a system of metal pegs that the wires are attached to. 110 punch down block is often used in telecommunications closets that connects station cabling to the trunk cabling that goes from an IDF to the MDF. Being the predecessors to patch panels, 110 punch down blocks were commonly used to support low-bandwidth Ethernet and token-ring networks.

What Is 110 Punch Down Block

A 110 punch down block is an updated version of punch down block, is the core part of the connection management system, used to connect wiring for telephone systems, data network wiring, and other low-voltage wiring applications. 110 type wiring block is flame retardant, injection-molded plastic to do the basic devices and the termination cabling system is connecting on it.

The 110 punch down block is designed for 22 through 26 gauge solid wire. This is the termination used on Cat5e Patch Panel Wall Mount, Cat 6 patch panel and RJ-45 jacks. They are also formed into block type terminations the size of small 66 blocks. The 110 blocks are designed for 500 MHz (1 Gb/s) or greater bandwidth. 110 blocks are acceptable for use with AES/EBU digital audio at sample rates greater than 268 KHz as well as gigabit networks and analog audio.

110 Punch Down Block Wiring Diagram

The specifications of 110 Connecting Block are as follows: 25 pairs 110 type wiring block, 50 pairs 110 type wiring block, 110 pairs 110 type wiring block, 300 pairs 110 type wiring block. The distribution frame package of 110 type wiring blocks should also include 4 or 5 blocks, connection block, blank labels, and tags folder and the base. 110 type wiring block system uses easy quick-fit plug-hop loops which can be simply rearranged, so it provides a convenient cross-connect to the non-professional and technical personnel management system.

How to Punch Down 110 Block with Tool

A Punchdown Tool is used to force solid wire into metal slots on the 110 punch down block. Present residences typically have phone lines entering the house to a sole 110 block, and then it is spread by on-premises wiring to outlet boxes all over the house in a star topology.

How to Punch Down 110 Block

Both styles of punch block use a punch down tool to terminate the wires to the block. To terminate a wire, you place it into the terminal and then push it down to make contact with the punch down tool. The punch down tool fits around a 66 block terminal or into a 110 punch down block terminal. One side of the blade is sharp to cut the wire off flush, this is normally marked on the tool with the word cut. Be sure to have this side oriented to cut off the loose end of the wire and not the end going to the other block. Hide extra cable behind the block in case you ever have to re-terminate a pair so that you don’t have to re-terminate the entire cable. More details on punch down tools and how to punch down 110 blocks, read How to Use a Punch Down Tool for 110 Block

Whatever the dimensions of the punch down tools are, usage is the same. Many tools have a dual blade that can be flipped depending on which style of block is in use.

4 Answers

I used to use a small screwdriver to hook phone lines into a panel, same principal.

The inexperienced woodworker and the very experienced person will be able to do these projects without any difficulty https://tr.im/qjCqV

Each and every one of the thousands woodworking plans and projects which are available are so well written so that even if you’ve never tried Woodworking before, or if you have 2 left hands, you would find woodworking a breeze

The Bottom Line

L-com’s EZ 110 Punch Down Tool + RJ45 Crimper (HT-110EZ) is a must- have for any network or telecom engineer who works with 110 blocks and RJ45 jacks.

Two data/telecom tools in one.

Makes crimping Ethernet cable easy.

Good at punching down 110 jack.

Only supports unshielded RJ45 plugs.

Only for 110 blocks.

Blade has 2,000 cycle use guarantee.

Applications, services and even hardware-based tech such as storage and servers, continue to move out of the datacenter and into the cloud. Still, many organizations have IT staff managing equipment in the datacenter and doing tasks like cabling for telephony and data. These folks are typically networking and/or telecom specialists and they lay the groundwork for smooth-running networks.

To successfully create Ethernet jacks that computers connect to and for terminating Ethernet cables in a way that does not impair the data signal, IT workers need the right tools. Crimpers are used to terminate RJ45 heads—the little plastic plugs that allow an Ethernet cable to fit either into an RJ45 wall jack or the Ethernet port on a computer. I’ve had numerous experiences with crimpers that did not have the right amount of pressure to make a good crimp as well as the sometimes-flimsy punch down tool that comes with RJ45 jacks—making wiring time-consuming and frustrating.

That’s why anyone doing network wiring will appreciate a combo tool such as L-com’s EZ 110 Punch Down Tool + RJ45 crimper. It’s not only a crimper for terminating Cat 5, 5e or 6 cables, but it also will punch down a 110 IDC RJ45 jack. It’s a quality piece of equipment.

The HT-110EZ has a weighty feel; it’s solid and easy to tell it’s well made. Yet, it’s still light enough to throw into a telecom bag and travel with it if you do wiring at multiple sites.

A blue handle serves as the crimping tool. The tool has a latch that you use to secure the handle into the punch-down part of the tool, making it more compact and easy to fit inside a cluttered workbag.

The crimping tool is made for unshielded modular RJ45 plugs. I found it real easy to terminate a network cable. I remember using some crimpers where it took all my hand strength to squeeze and get the cable crimped. Those subpar crimpers are more like hand crampers— especially if you are dealing with lots of cables!

The punch down part of the tool is effective as well. I did a pin-out on a modular 110 RJ45 jack. The blade easily cut through the twisted pair wires. The HT-110EZ provides consistent, quick RJ45 jack wiring—so important for good data communications.

There seems to be a lot less pressure on the jack doing a punch down using the HT-110EZ over an impact tool. One consideration though, with an impact tool you can maneuver a little more with punching down a jack and can check how your wires are positioned before punching down. Since you insert the TJ45 plug into the HT-110EZ’s groove for the keystone jack, you have to make sure the cables are all set correctly before inserting the jack into the tool and punching down.

There are a few caveats: If you have a mixed infrastructure, for example, you may have 110 blocks, a 66 block and maybe even a Krone panel, this tool is limited for you, as it is only for 110 blocks. L-com does offer impact tools which have blades you can switch out for different blocks.

Also, once the 2,000 cycle blade use limit is reached, the company won’t replace the blade or anything like that. It recommends getting a new HT-110EZ. If you do a lot of cabling work, you may go through the blade in a short time.

Still, this is a tool I would have loved back in the days when I had to wire hundreds of jacks under deadline and regularly made custom network cables. Datacenter wiring remains an integral part of IT network/telecom duties. You need the right tool for the job and L-com’s HT-110EZ is the right tool at the right price and earns a 4.5 out of 5 star Editors’ Choice for networking tools.

Fiber Patch Cords, SFP/SFP+/QSFP, WDM Assemblies, etc

Punch down tool, also called punch down tool or krone tool (named after the KRONE LSA-PLUS connector), is a small hand tool used by telecom and data network technicians to install wiring for telephone, computer and various audio network, designing for inserting wire into insulation-displacement connectors on punch down blocks, patch panels, keystone modules, and surface mount boxes (also known as biscuit jacks). Its name is derived from the method by which the tool pushes a solid copper wire between metal blades on the connection block and cuts off the excess by punching the tool, driving the tool blade through the wire.

Punch down tool is commonly used for termination works in the coppper network builted by twisted-pair cables like the Cat5, Cat5e, Cat6 and some newer standard Ethernet cables. With cables terminated with keystone jacks, cross-connect blocks or patch panels, networks run smoothly, enhancing working efficiency and reducing losses. For instance, it is widely used by IT staff to ensure successful connections between computers and data centre, maintaining a high level of transmission.

Note: It is essential that the tool blade should not cut throughout the wire insulation to make contact, but rather the sharp edges of the slot in the contact post itself slice through the insulation. In addition, punch down tool is also used to cut off excessive wire in the same operation.

By Gregory Vaks | Last Updated May 7, 2020

A punch down tool is a handheld mechanism used to install wiring, typically for telephone or internet networking but also at recording studios, radio stations and television networks.

Establishing a successful and secure network connection isn’t exactly a DIY project, so a punch down tool is more suited to trained network technicians.

Prior to purchasing a punch down tool, you’ll want to consider if its blades are interchangeable or reversible. You’ll also want to consider if the handle is designed ergonomically and if the impact is adjustable.

Here are the top-rated punch down tools we found to make your life easier on the job.

What is the Best Punch Down Tool?

Not only does the TRENDnet punch down tool support interchangeable blades, but they are also reversible. That makes it easy to switch the cutting end during a project with no need to hunt down a brand new blade.

If you do need a new blade, however, this particular punch down tool has blade storage inside of the handle. No more lost blades. The handle itself is slightly wider than other models, too. This can make it easier to grip and use while still being easy to see around.

With this punch down tool, you also get a full one year warranty from the manufacturer, on top of any vendor guarantees.

How Much Do Punch Down Tools Cost?

This guide will not only help you to understand important factors but also select the best product.

This wiki has been updated 11 times since it was first published in November of 2018. Every network technician needs a good punch down tool in their bag. These simple devices are used for pressing wires into posts, pushing them into the slot, snipping the insulating sheath, and securing the cable. Many of the options on this list are spring-loaded to save your hands from repetitive stress, while others include additional tools, like spudgers and hooks, to make your job even easier. When users buy our independently chosen editorial recommendations, we may earn commissions to help fund the Wiki. Skip to the best punch down tool on Amazon.

This wiki has been updated 11 times since it was first published in November of 2018. Every network technician needs a good punch down tool in their bag. These simple devices are used for pressing wires into posts, pushing them into the slot, snipping the insulating sheath, and securing the cable. Many of the options on this list are spring-loaded to save your hands from repetitive stress, while others include additional tools, like spudgers and hooks, to make your job even easier. When users buy our independently chosen editorial picks, we may earn commissions to help fund the Wiki. Skip to the best punch down tool on Amazon.

10. Klein Tools

9. Cable Matters

8. Jonard EPD-91461

7. Greenlee 3579 SurePunch

6. Tripp Lite

5. Southwire Tools & Equipment Professional

4. Epsilont EPS2000PD

3. Vastar Impact

2. Fluke D914S

1. Trendnet TC-PDT

Editor’s Notes

January 03, 2019:

Since most punch down tools follow the same basic layout, it’s difficult to rank them — there aren’t exactly a lot of bells and whistles to distinguish them. With that in mind, we focused on durability, ergonomics, and blade quality when making our selections. Every item on this list will get the job done — some just last a lot longer and make your life a lot easier in the meantime.

Related Wikis

After getting his bachelor’s from the University of Texas, Quincy Miller moved out to Los Angeles, where he soon found work as a copywriter and researcher, specializing in health and wellness topics for a major online media brand. Quincy is also knowledgeable about home improvement, as he’s had extensive experience with everything from insulation to power tools to emergency room trips, sometimes in that order. Sharing a home with three dogs and a couple of cats has forced Quincy to learn as much as he can about pet supplies, animal nutrition and, most importantly, the best ways to tackle the mountains of fur that accumulate in every corner of your home.

Step 1: Make sure the stripper is adjusted properly on a scrap piece of cable. The Stripper should be adjusted to only score the jacket to make removing it easier and not nick the twisted pairs. Using a Coaxial Stripper strip around 1 inch of the jacket off. Be careful not to nick the conductors as this will cause the wire to break or short out the connection causing problems down the road. Inspect all wires for damage before proceeding to step 2.

Step 2: Straighten the pairs out completely and lay them over the top of the keystone jack noting the color pattern for the 568b wiring. Note: Each keystone jack is slightly different in how they are labeled and how the colors are arranged. The 568B standard is most commonly used and ends of the cable must have the same standards to communicate. We have the 3 most common keystone jack styles pictured here. The first jack pictured has the 2 standard pairs on the right, and the 2 variable pairs on the left. The A standard is the center column and the B standard is on the left. Both A and B standard applies to the right side of the jack. The solid color box with the lower right corner missing represents the solid color wire with the white stripe. The white box with the colored tip represents the white wire with the colored stripe.

The second jack pictured here has both A and B standards on both sides of the jack, with the color code running down the center. The solid color rectangle represents the solid color wire with the white stripe, wile the half white half color rectangle represents the white wire with the colored stripe. The third jack pictured here has the A and B standard codes labeled on the outside of the jack. With the A standard on top and the B standard on the bottom. The solid box represents the solid wire with the white stripe Wile the box with the white diagonal stripe going throught the middle, represents the white wire with the colored stripe.

Step 3: Keeping the pairs as twisted as possible press the wire into the correct groove with your thumbs. If you completely straighten the wires to run them through the jack you will risk cross talk between the pairs.

RJ45 patch panels provide a useful solution for cable management in data centers and other high-density environments. In the market, two types are offered like punch down and feedthrough patch panel. But consumers often find it’s difficult to make a decision on which one is better. This article is going to help your dilemma.

Punch Down Patch Panel

Punch down types are available in Cat5e or Cat6 patch panel. On the front plate, RJ45 ports (usually 24 ports) are used to directly connect Ethernet copper cable. All ports are numbered for easy identification. In the rear, it’s patch panel module with color markings for punching down Ethernet cable. Color coded labels are designed for T568A and T568B wiring configurations.

How to Punch Down a Patch Panel?

If you select punch down patch panel, firstly you need to terminate all cables into the patch panel.

When the punching down process is completed, you can install the patch panel into the racks with screws.

Feedthrough Patch Panel

Feedthrough patch panel provides patching without punching down the wires to the ports. There are generally Cat5e and Cat6 feedthrough patch panel configured in 1U (24 ports) or in 2U size (48 ports). Each feedthrough patch panel has both RJ45 ports on the front and rear side. And ports on front side are numbered for easy identification and installation. With feedthrough patch panel, the Ethernet patch cables can be inserted into the ports directly in an easy and fast way. The patch panel is quite suitable for high-density network system, which can protect cable and improve cable management efficiency.

Feedthrough Patch Panel Installation Steps

Install the feedthrough patch panels in lay racks or communication cabinets.

Punch Down Patch Panel and Feedthrough Patch Panel, Which One Is Better?

Today’s flashback is also going to be a HOWTO, and vaguely related to yesterday’s Rackmount HOWTO. Today I’m including a HOWTO for understanding how building wiring works.

When I first looked at house wiring in a moderately complex 8 story building, I was sort of mystified. It was only after literally tracing wires and numbers around the various wiring closets that I understood what was happening.

This howto deals specifically with 66-blocks, but 110 blocks are also becoming common, just not in my neck of the woods.

Punch down blocks are used for when you need to run wires long distances, typically between distribution points ( things like the MDF, or Main Distribution Facility, otherwise known as the main telco room on the primary floor of the building), comms closets, and the like. They are used, rather than normal RJ45 jacks, because they are simpler, less prone to breaking, and don’t introduce much, if any, extraneous electrical interference to the wire.

For the next few paragraphs, please refer to the following picture, which is a clear, understandable example of a punch down block:

Those grey things in the middle are termination points for single wires. When you deal with punch down blocks, you deal in pairs of wires, and you get one wire to one grey clip. Pretend there is an imaginary line down the middle of that patch panel, because the pairs on the left are separate from the pairs on the right. If you number a line going across, 1 2 3 4, 1 and 2 are a pair, 3 and 4 are an entirely different pair. In the picture, you can tell, because of the numbering scheme they’ve used. There are 4 clips for a pair, but only 2 clips are wired in the beginning. Each pair is numbered, so the phone company can say “Turn on pair 3044”.

Now, at our building, the phone company’s lines are on the right side of the wall. On the left side of the wall is another huge array of punchdown blocks. These are for the “house wiring”. When they built the building, they pre-ran hundreds of pairs of wires to each floor from this room, so that they wouldn’t have to redo it every time someone ordered a T1. Each wire to each floor is terminated to a pair on the left side of the wall in exactly the same manner as the one on the right (including leaving one set empty).

To connect the two sides, you run a twisted pair of wires (it looks like you took a section of cat5, stripped off the sheathing, and just used one set of wires) from the right side of the wall (from the pair of grey clips we left open on #3044) to the left side of the wall (say #514, the 14th pair to the 5th floor, again using the empty grey clips). If you look again at that picture, you can see 3043 has been wired across, because all 4 wires are clipped in, but 3044 has not, since only the rightmost clips have wires.

At this point, you have two wires coming in from the phone company to the punch down blocks on the right. Then you’ve got wires connecting those punch down blocks to the “house wiring” punchdown blocks on the left. Then you’ve got vertical wiring up to the floor that the wire ends at.

In the comms closet on that floor (also known as the IDF, or intermediate distribution facility), you have a very similar situation. On the right hand side, you’ve got the punch down block where the vertical cabling from the MDF terminates, and on the left, you’ve got a punch down block where the actual wires that end up in your office are terminated. You use another twisted pair of wires to connect the two sides, and at that point, the wire that ends up in your office is connected directly to the phone company, albeit through several punch down blocks and lots of wire.

Now, when it comes into your office, hopefully someone has had the courtesy to install a patch panel for you. The patch panel looks like this on the front:

and this on the back:

As you can tell from the photo on the back, wires are typically matched up color for color when it comes to straight CAT5 cables. When it comes to things like wiring T1s, you’re only using two wires, so as long as you remember which one goes to what wire, you’re ok.

So, i review, we’ve got phone company wires coming in, and terminated in the MDF. They’re connected across to the house wiring, which is run vertically to the IDF, and from the IDF, it goes to your space. All of this is accomplished with those magic little grey clips.

Now, if only the wires would go in there. It turns out that there’s a trick. Or a tool, really, called a punch down tool (creative, eh?). The cheapest punch down tool I’ve ever seen is a buck. It’ll work in a pinch, but the one you want is here:

As for maintenance, there’s not really much that can go wrong in a patch panel, as long as no one comes in and starts pulling on wires. Typically there’s a plastic case that goes over the entire block to prevent accidental snags from pulling wires loose.

The best advice is to document everything you can. Leave a hard copy of the documentation in the comms closet so that you can see what’s been done. Lots of times, the telephone tech will “tag” the lines that he’s installed on the right hand side. The tag usually has the numbers of the pairs that are activated on the telco side, and the phone numbers (or circuit IDs) that match those pairs.

(Photos courtesy of lil 1/2 pint, techmsg, dmitrybarsky)

Introduction: Leatherman Punchdown Tool

Something that I always have at my side, is my Leatherman Wave. It has all kinds of tools that can help out at a moments notice except for one, a punchdown tool! As a system admin, sometimes I have the need to terminate a keystone jack or punchdown block and I don’t have room in my pocket to carry a real punchdown tool with me everywhere I go. Now with this quick mod, I can! Everyone that has a Wave knows about the “large screwdriver” aka “pry-bar.” I never understood it’s true meaning since you already have four different screwdrivers to choose from. Now you can ditch that and have a nice useful punchdown tool.

Step 1: Thin Down the Tip!

The first thing you will need to do is use a bench grinder or dremel to thin the metal down to about half the current thickness, 3/8″ from the tip in order to make it fit the block. Be careful not to make the tip sharp, you don’t want to cut the wire you’re trying to punch down.

Step 2: Make It Shine!

Next you will want to file down and then sand both sides where you ground the thickness down. This will make it smooth and shiny.

Step 3: Cut the Slot!

Now you can begin the fun part of cutting the slot for the “vampire teeth” of the punchdown block. Use your dremel to cut slightly into the middle of the tip. You will want to cut 1/8″ into the tip. You may want to widen the slot slightly. See the picture for reference.

Step 4: Finished!

Hooray, you now have a functional non-impact punchdown tool on your Leatherman! Go try it out!

Be the First to Share

Did you make this project? Share it with us!

Recommendations

Mason Jar Speed Challenge

Pumpkin Challenge

Halloween Contest

26 Discussions

if someone doesn’t need a punch down tool, make it sharper and use it as a leather stitching tool.

wow – put a trademark on that.

Maybe it’s not a screwdriver but a chisel?

What dremel bit are you using? I recently got a dremel and am very confused as to which bit or wheel to use for what purpose.

i feel very lucky today because it found a perfect condition leatherman wave on a bench at the beach

Reply 10 years ago on Introduction

lol, wave, at the beach

Reply 10 years ago on Introduction

That’s like a joke, but not! (sarcasm)

Very good Instructable! I’m IT technician and it is a good punchdown. As here in Brazil we haven’t Leathermans for sale (nor SOG or Gerber) I’ve buyed a cheap US$ 10 multitool and try this mod and it fits very well! The standard screwdriver of my multitool is very thin, so I just need to cut the “tooth” on the middle of the screwdriver and, as you tell, “Hooray”! I have my punchdown on my multitool! My cheap multitool is very nice to IT jobs, because it have an implement that fits driver bits and I carry a set together. To carry all, I use a good pistol reloader case, as the multitool haven’t original case (and if does, I presume that will not be so good). I have uploaded a pic of my mod to all of you! Hope someday these Leathermans can be found here! Sorry about english mistakes! Cesar

Is there a reason you’re robbing people’s vehicles? If you really stole something out of someone’s car, I think the owners of this website should call the police on you. They don’t need your address, just the IP you’re on when posting messages.

Reply 12 years ago on Introduction

With what warrant? “He posted on the internet so it must be true” won’t hold up in court too well buddy.

Reply 12 years ago on Introduction

Anyone driving a Hummer has a strong need to learn not to become too attached to their things. But you don’t have to be the one to teach them this lesson. Stealing things isn’t good for you. Trust me.

Reply 12 years ago on Introduction

Well here’s how it goes. My dad owns a used car lot. I go through his cars and take stuff sometimes. If I don’t his employee will. I got my bench press the same way.

Reply 12 years ago on Introduction

You can do anything you want. Just make sure its what you want. You’d feel better about your bench press if you could brag that you built it, even better if you designed, and more so if you did an instructable on it.

TC-PDT (Version 1.1R)

TRENDnet’s professional punch down tool, TC-PDT with 110 and Krone blades, inserts and cuts terminations in one operation. Adjustable high and low actuation setting accommodates termination requirements or user preference. With spare storage that helps prevent blade loss, the precision blades are conveniently interchangeable and reversible between 110 and Krone. The punch down tool offers reliable, easy-to-use operation at an affordable price.

Company

Press

Products

Support

Partners

Subscribe

Follow Us On

© Copyright 2020 TRENDnet, Inc. All Rights Reserved. Privacy Policy and Disclaimer. Cookies Policy

Introduction: Leatherman Punchdown Tool

Something that I always have at my side, is my Leatherman Wave. It has all kinds of tools that can help out at a moments notice except for one, a punchdown tool! As a system admin, sometimes I have the need to terminate a keystone jack or punchdown block and I don’t have room in my pocket to carry a real punchdown tool with me everywhere I go. Now with this quick mod, I can! Everyone that has a Wave knows about the “large screwdriver” aka “pry-bar.” I never understood it’s true meaning since you already have four different screwdrivers to choose from. Now you can ditch that and have a nice useful punchdown tool.

Step 1: Thin Down the Tip!

The first thing you will need to do is use a bench grinder or dremel to thin the metal down to about half the current thickness, 3/8″ from the tip in order to make it fit the block. Be careful not to make the tip sharp, you don’t want to cut the wire you’re trying to punch down.

Step 2: Make It Shine!

Next you will want to file down and then sand both sides where you ground the thickness down. This will make it smooth and shiny.

Step 3: Cut the Slot!

Now you can begin the fun part of cutting the slot for the “vampire teeth” of the punchdown block. Use your dremel to cut slightly into the middle of the tip. You will want to cut 1/8″ into the tip. You may want to widen the slot slightly. See the picture for reference.

Step 4: Finished!

Hooray, you now have a functional non-impact punchdown tool on your Leatherman! Go try it out!

Be the First to Share

Did you make this project? Share it with us!

Recommendations

Mason Jar Speed Challenge

Pumpkin Challenge

Halloween Contest

26 Discussions

if someone doesn’t need a punch down tool, make it sharper and use it as a leather stitching tool.

wow – put a trademark on that.

Maybe it’s not a screwdriver but a chisel?

What dremel bit are you using? I recently got a dremel and am very confused as to which bit or wheel to use for what purpose.

i feel very lucky today because it found a perfect condition leatherman wave on a bench at the beach

Reply 10 years ago on Introduction

lol, wave, at the beach

Reply 10 years ago on Introduction

That’s like a joke, but not! (sarcasm)

Very good Instructable! I’m IT technician and it is a good punchdown. As here in Brazil we haven’t Leathermans for sale (nor SOG or Gerber) I’ve buyed a cheap US$ 10 multitool and try this mod and it fits very well! The standard screwdriver of my multitool is very thin, so I just need to cut the “tooth” on the middle of the screwdriver and, as you tell, “Hooray”! I have my punchdown on my multitool! My cheap multitool is very nice to IT jobs, because it have an implement that fits driver bits and I carry a set together. To carry all, I use a good pistol reloader case, as the multitool haven’t original case (and if does, I presume that will not be so good). I have uploaded a pic of my mod to all of you! Hope someday these Leathermans can be found here! Sorry about english mistakes! Cesar

Is there a reason you’re robbing people’s vehicles? If you really stole something out of someone’s car, I think the owners of this website should call the police on you. They don’t need your address, just the IP you’re on when posting messages.

Reply 12 years ago on Introduction

With what warrant? “He posted on the internet so it must be true” won’t hold up in court too well buddy.

Reply 12 years ago on Introduction

Anyone driving a Hummer has a strong need to learn not to become too attached to their things. But you don’t have to be the one to teach them this lesson. Stealing things isn’t good for you. Trust me.

Reply 12 years ago on Introduction

Well here’s how it goes. My dad owns a used car lot. I go through his cars and take stuff sometimes. If I don’t his employee will. I got my bench press the same way.

Reply 12 years ago on Introduction

You can do anything you want. Just make sure its what you want. You’d feel better about your bench press if you could brag that you built it, even better if you designed, and more so if you did an instructable on it.

Product code: 83108 Pack size: Each

– Change your branch

Check stock in your local branch

Save for later

Sign in to your account

Product Details

Please note items delivered by our suppliers are not available for the options above. Delivery times may vary.

Due to current trading conditions we have suspended our Call & Collect service until further notice.

If you are using our Click & Collect service please note the following:

Fiber Patch Cords, SFP/SFP+/QSFP, WDM Assemblies, etc

When it comes to punching down Ethernet patch panel, unlike feed through patch panel which provides patching without punching down the wires to the ports, punch down patch panel is a kind of network patch panel that should punch down Ethernet cable on the rear side. On the front plate, RJ45 ports, marked with number for easy identification, can be directly connect Ethernet copper cable. For example, simply punch down the twisted pair cabling in the back of the 24 port patch panel and you are ready to plug in RJ45 patch leads in the front.

Punch down types are available in Cat6 or Cat5e patch panel. Category 6 cables have stricter standards for reducing system noise and avoid crosstalk, much better than Cat5 or Cat3, which means less network interference and better performance. Here comes the question: how to punch down Cat6 into patch panel.

After experiencing myself and watching countless videos performed by others, I summary the procedure into the brief seven steps and hope it can help you when fixing the devices.

/wedata%2F0025965%2F2011-08%2F1-Punchdown-or-punch-down-tool-with-Krone-fitted-a.jpg)