methane slip что такое

Is Internal Combustion Engine Methane Slip Harmful to the Environment?

Tighter regulations on exhaust emissions are prompting rapid change within the global shipping industry. Orders for scrubber systems have soared higher than before, suppliers of emissions monitoring software are rapidly taking increasing orders, and the market for natural gas-powered engines continues to break new ground.

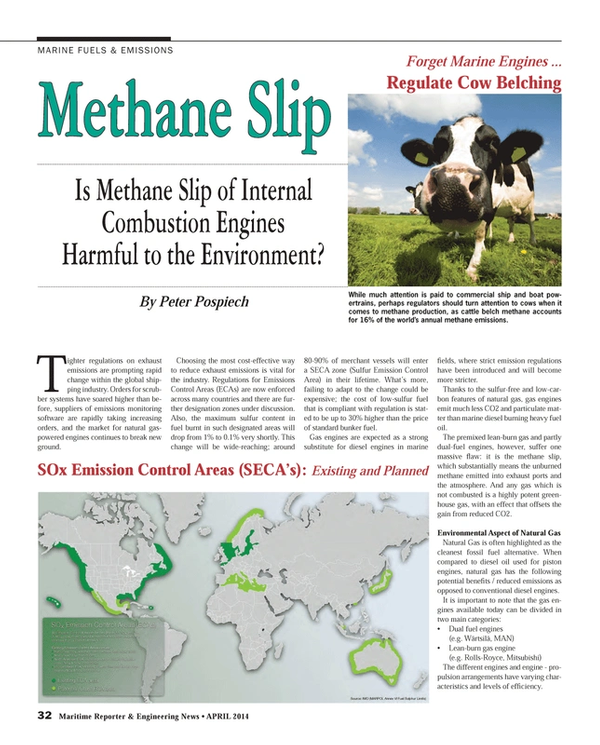

Choosing the most cost-effective way to reduce exhaust emissions is vital for the industry. Regulations for Emissions Control Areas (ECAs) are now enforced across many countries and there are further designation zones under discussion. Also, the maximum sulfur content in fuel burnt in such designated areas will drop from 1% to 0.1% very shortly. This change will be wide-reaching; around 80-90% of merchant vessels will enter a SECA zone (Sulfur Emission Control Area) in their lifetime. What’s more, failing to adapt to the change could be expensive; the cost of low-sulfur fuel that is compliant with regulation is stated to be up to 30% higher than the price of standard bunker fuel.

Gas engines are expected as a strong substitute for diesel engines in marine fields, where strict emission regulations have been introduced and will become more stricter.

Thanks to the sulfur-free and low-carbon features of natural gas, gas engines emit much less CO2 and particulate matter than marine diesel burning heavy fuel oil.

The premixed lean-burn gas and partly dual-fuel engines, however, suffer one massive flaw: it is the methane slip, which substantially means the unburned methane emitted into exhaust ports and the atmosphere. And any gas which is not combusted is a highly potent greenhouse gas, with an effect that offsets the gain from reduced CO2.

The true reduction of greenhouse gas emissions in each individual case will of course depend on the total efficiency of the chosen alternative. It should be noted here, however, that methane slip, will negatively influence the reduction of greenhouse gases significantly, and in worst cases eliminate the gains from CO2 reductions. In consideration of the fact that CH4 is about 20-25 times more powerful than CO2 as a greenhouse gas during a 100 year time span, release of even small volumes of methane easily spoils the potential gains.

Available Methane

Apart from gas fields, an alternative method of obtaining methane is via biogas generated by the fermentation of organic matter including manure, wastewater sludge, municipal solid waste (including landfills) or any other biodegradable feedstock, under anaerobic conditions. Rice fields also generate large amounts of methane during plant growth. Methane hydrates/clathrates (ice-like combinations of methane and water on the sea floor, found in vast quantities) are a potential future source of methane. Cattle belch methane accounts for 16% of the world’s annual methane emissions to the atmosphere. One study reported that the livestock sector in general (primarily cattle, chickens, and pigs) produces 37% of all human-induced methane. A more recent study found that at a conservative estimate, at least 51% of global greenhouse gas emissions were attributable to the lifecycle and supply chain of livestock products, meaning all meat, dairy and by-products, and their transportation.

Compared to this enormous amount of direct methane emission, the contribution to total world greenhouse gas emission of marine engines is very minute.

Methane Slip Reduction

In connection with gas engines, while NOx emissions are negligible, emissions of unburnt methane are a subject of increasing attention for all mayor engine manufacturer

“The amount of unburnt gas following combustion in a Wärtsilä gas engine is small,” said Ingemar Nylund, Director Research & Development. “It is trapped in clearances in the combustion chamber (piston rings, the anti-polishing ring, valve seats etc.) where the air-fuel ratio means that the gas does not burn during combustion but is released unburnt with exhaust gases during cylinder scavenging. We ensure that methane slip is minimized in our engines in two ways,” he continued. “By continuous development of the combustion chamber technology to improve the combustion process, new Wärtsilä products have to be the reference in terms of engine efficiency, output and greenhouse gas emissions, and by the oxidation of unburnt methane using a catalyst. And with our latest development, our low-pressure 2-stroke engine, the methane slip is almost negligible.

The “methane slip” inherent in the RT-flex 50DF engine is less than what is found in the equivalent 4-stroke engine and still results in 25% less equivalent CO2 emissions, because the combustion has much more time to burn more completely, which is not the case in 4-stroke engines. On top of this: the RT-flex DF engines have the potential to further reduce the methane slip by further developments, which means: ‘Direct’ methane slip can be avoided by correct gas admission valve timing, the use of pre-chamber technology to have complete combustion and an optimized combustion space to avoid ‘dead volumes. This well-proven technology is commonly featured in Wärtsilä solutions packages and we’re working hard to further reduce its size and cost.”

And well-known engine manufacturer Rolls-Royce claims to have lean-burn 4-stroke gas engines with very small amounts of methane slip in the range of appr. 3-4 g/kWh. But, nevertheless, as Tobias Haack, Sales Manager, said: “we are working on this to reduce this amount because it is unburned fuel – and unburned fuel means higher fuel consumption and that increases operation costs.” According to the company, it is focussing on extremely close control of combustion in every cylinder at all times, the design of the combustion chamber using the latest computer aided design tools and optimised turbo charging. MAN Diesel & Turbo explains its high pressure 2-stroke engines concept does not have any methane slip.

The ME-GI concept is based on direct gas injection with the engine operated as a conventional diesel engine. Thus, no gas is present during the compression stroke or scavenging period, minimizing methane slip to a level comparable to operation on conventional liquid fuel. Recent tests of ME-GI engines have revealed a measured methane slip in the order of 0.2 g/kWh, independent of engine load. This slip is 20-40 times lower in comparison to the methane slip recorded for the most modern, state-of-the-art, dual-fuel engines.

The global warming potential (GWP) of methane is 72 times as high as CO2 over a 20 year time interval. Thus, when calculating total GWP, in addition to CO2, CH4 must be considered as well. Taking the methane slip of the ME-GI engine into account, the total GWP is still significantly lower than normal fuel-oil operation, approximately 17-20% lower. But it is not only the combustion engine, also in the supply chain from the terminal all the way to their combustion in the engine climate change emissions may be formed (gas leaks = methane slip). Here, the escape of methane is of specific importance by means not only of gas leaks but also of the methane slip of pipe connection, couplings etc. This is a loss of usuable energy which must be avoided.

It is without doubt that the very large amount of all human-induced methane (primarily cattle, chickens, pigs, etc.), and in addition naturally existing methane on earth, can hardly be reduced. But it is in our hands to reduce possible methane slips in combustion engines and not to forget the supply chain, with all technical possibilities we have.

Engine manufacturers are on the best way to do so. In general methane harms our environment, but compared to the enormous amount of direct methane emission, the contribution to total world greenhouse gas emission of marine engines is very minute.

Read Is Internal Combustion Engine Methane Slip Harmful to the Environment? in Pdf, Flash or Html5 edition of April 2014 Maritime Reporter

Overcoming Methane Slip, Rolls Royce Marine Builds Spark-Ignited LNG-Powered Engines

Share this article

Leading the way with gas engines for marine propulsion

Liquefied natural gas (LNG) is becoming a popular fuel for ships, with Rolls-Royce a leading manufacturer of engines for propulsion and electric power generation.

Originally the reason for adopting LNG instead of liquid fuel was to reduce emissions of NOx, sulphur oxides, and particulates (smoke/soot). An added benefit came from the chemical composition of methane, in the form of much reduced CO2 emissions. A negative feature of LNG fuel is that any gas which is not combusted is a highly potent greenhouse gas, with an effect that offsets the gain from reduced CO2.

Although various media have highlighted “methane slip” from marine engines, the contribution to total world greenhouse gas emissions is minute. Direct emission of methane from agriculture, mining, shale oil and gas production, industry and natural seepage is enormous by comparison.

Early marine gas engines from Rolls-Royce were the Bergen K-series. These were related to several hundred engines delivered for land power generation burning various types of fuel gas, including methane–rich landfill gas that would otherwise have escaped to add to greenhouse gas effect. This engine type had less methane slip than competing engines, but Rolls-Royce was aware of the desirability of further reducing methane slip, and so developed the C-series gas engines and the larger B-series in-line and BV-series V-engines based on the company’s lean-burn Otto cycle technology. Extremely close control of combustion in every cylinder at all times, design of the combustion chamber using the latest computer aided design tools, and optimised turbocharging, has cut methane slip to very low levels. These engines can either be used for generator drive in a gas engine/electric transmission or for driving the propeller through a mechanical transmission directly.

The greenhouse effect of methane is estimated differently by various government authorities and environmental organizations as between 21 and 25 times that of CO2 for the same quantity. Rolls-Royce uses a rather pessimistic figure of 23 in its calculations, and presents the engine emissions figure as the net reduction of CO2 emissions after accounting for the negative effect of the very low methane slip. For example, the reduction of CO2 itself in the gas engine compared with an engine running on distillate diesel or heavy fuel is up to 30%. Even after allowing for methane slip, the total GHG reduction is very great.

This means that the Rolls-Royce marine gas engine ranges fulfil the requirements for operation in Emission Control Areas (ECA) and the very strict IMO Tier III rules that come into force in 2016. Emissions of NOx are about 92% less than liquid fuel engines, SOx and particulates are negligible, and even after allowing for the effect of methane slip the total GHG emission is about 22% lower than a comparable diesel engine. The thermal efficiency of these engines is also very high, in the range 49-50.3% depending on the engine type. Other advantages of these gas engines include greatly reduced risk of oil spills, a cleaner engineroom, and the absence of smoke.

Currently Rolls-Royce Bergen gas engines are in service in, or on order for, ferries, roro vessels, tankers, coast guard ships and offshore support vessels. To date, 35 marine engines have been sold, and about 500 land engines, with cumulative running time of over 20 million running hours.

Following excellent experience with the LNG fueled engines in five double-ended ferries in intensive service connecting main road routes on the west coast of Norway, a second generation and larger ferry has now been delivered. Boknafjord can carry 242 cars or equivalent, and 589 passengers. Three Rolls-Royce C26:33 nine cylinder gas engines drive generators to power four of the company’s Azipull steerable thrusters to maximise the vessel’s efficiency and manoeuvrability.

Torghatten Nord, operating ferries in tough weather conditions in the north of Norway, is also going for gas. Four vessels now being built in Poland will be powered by lean burn Rolls-Royce gas engines with mechanical drive to the propellers.

Ferries are a testing environment for engines. “If you can survive the ferry cycle you can survive anything. The repeated heating up and cooling down puts a massive strain on the engines,” says Odd Magne Horgen, General Manager for Engine Sales in Rolls-Royce.

The world’s coastal and short sea vessel fleet is ageing, and alert operators are now ordering future orientated designs with LNG as the fuel. For its fleet renewal programme, Norlines has ordered 5,000dwt vessels of Rolls-Royce design to carry roro freight, containers and pallets on its North Sea/Baltic routes. The chosen power is a single B35:40L9 gas engine driving the controllable pitch propeller through a gearbox. Propeller and rudder are integrated hydrodynamically to give a very efficient and low emissions propulsion system.

Offshore service vessels can profit from changing to gas fuel, as well as reducing marine emissions. An example is Island Offshore, who are adding two platform supply vessels of Rolls-Royce UT 776 CDG design with C-series LNG fueled engines to their fleet.

Discussions are also in progress with a Japanese owner about the propulsion of a 70,000dwt bulk carrier using twin Bergen gas engines, taking LNG fuel and medium speed engines into this type of vessel.

As the LNG bunkering infrastructure expands this fuel becomes a realistic choice for commercial shipowners. The major classification societies now have rules for LNG fuelled vessels, and Rolls-Royce can engineer and supply gas engine installations, from the engine itself through the propulsion system to the design of the whole ship.

The menace of methane slip

Despite its many virtues as a marine fuel, LNG has an Achilles heel – methane slip

Greenhouse gases (GHG) or nitrogen oxides? In the fight to reduce emissions, it appears that shipping companies are being forced to make a choice to avoid one or the other, but not both.

A series of recent studies show that LNG-fuelled engines give off less CO2 than diesel-powered units because LNG contains less carbon and more energy per mass unit. However, the fuel’s widely acknowledged Achilles heel is methane slip, the loss of a GHG into the air.

Class society Bureau Veritas explains in a white paper issued in September entitled In Engines as well as Cargo Tanks, LNG is Powering Ahead: “Caused by incomplete LNG combustion in the ship engine, methane – a potent GHG – is emitted into the atmosphere, partly offsetting the CO2 emissions reduction.” The paper continues: “This is a key area for technological development, as experts are working to improve the design of engines to limit methane slip.”

Nor is there any time to lose, particularly for the deep-sea fleet which has fewer propulsion options than short-sea vessels, which can resort to alternative forms of propulsion such as batteries. As the LNG fleet expands – the global order book for 2019 lists 17% of LNG-powered newbuilds in terms of gross tonnage – the pressure is on engine makers to cut methane slip to negligible levels.

IMO is also on the case, tasking working groups in 2020 to come up with “concrete proposals to reduce methane slip and emissions of volatile organic compounds.” In time this may lead to engine-makers being handed regulations that will force them to reduce methane slip in dual-fuel and gas engines.

High uncertainty

“For various reasons there is high uncertainty about which fuels will be used in the marine sector in the future,” pointed out the director of research and development for injection systems specialist Woodward L’Orange, Clemens Senghaas, at the Cimac conference in 2019. “Ignoring methane emissions would lead to a dangerously wrong choice of technology.”

Methane slip comes down largely to the efficiency of the combustion cycle. Citing recent studies with high-pressure engines, class society DNV GL explains that they can be tuned to slash tank-to-propeller GHG emissions by between 20-40% compared to marine gas oil-fuelled propulsion. By comparison,n low-pressure engines reduce such emissions by between nothing and 18%.

Enginebuilders are now toiling to reduce the amount of pollutants escaping from the engineroom, whether methane or carbon. For instance, MAN Energy Solutions, which has been working on methane slip for years, says its towering ME-GI engine using high-pressure gas injection “dispenses with the need for power derating and eliminates the significant problem of methane slip and resulting CO2 emissions.”

Long-term benefits

Yet while the transition from heavy fuel oil continues to pose challenges, many see it as a long-term environmental benefit. “Moving away from burning high-sulphur fuels in marine propulsion engines yields an opportunity to develop novel technologies for both the combustion chamber and the design of lubricating systems,” enthused Switzerland-headquartered WinGD’s director of research and development, Konrad Räss, citing improved resistance to corrosion among other important consequences that will be welcomed in the engineroom.

In short, the emissions regulations offer a window of opportunity which WinGD believes will encourage new technologies that deliver savings in terms of capital and operating expenditure for its two-stroke engines.

In the fight to reduce methane slip, the choice of fuel is a vital factor. And here LPG has its supporters. Like LNG, methanol and ethane, LPG burns cleanly with low emissions while releasing relatively little methane. The global warming potential value – an important number for regulators – of propane and butane, basic elements of LPG, is relatively low.

The fuel has other virtues, such as being plentiful on global markets. Unlike LNG it does not have to be shipped at cryogenic temperatures. It is more easily stored, is a long-established fuel with an extensive global infrastructure and it has lately become cheaper to buy because of a steady increase in available volumes.

Alfa Laval’s Robert Comelli, business manager for fuel conditioning systems in the marine division, is a supporter of LPG. He told the Cimac conference in a paper entitled Innovative LPG fuel supply system for MAN B&W LGP-P engines: Design challenges and performance results: “There is already a huge network of LPG import and export terminals in use worldwide. These are generally already built for a wide range of vessel sizes, making it relatively easy for local storage providers to add bunkering equipment in their facilities and [so] capitalise on the supply and sale of LPG as a fuel.”

Alfa Laval has adopted a multi-pronged solution to methane slip in LPG. Its engineers developed a new pumping technology, a high-pressure heat exchanger, and an automated control system that can pump the LPG at a rate that is constantly proportional to the fluctuating engine load that would be expected to occur in heavy weather.

However, no fossil fuel ticks all the boxes in methane slip. As Mr Comelli also pointed out, LPG may contain contaminants, for instance particles of sand and dust, that can clog up fuel lines and lead the vessel to stop and vent fuel.

Not resting on its laurels, in a joint project with MAN Energy Solutions, Alfa Laval is working on sea-going engines that will run on even cleaner fuels than LPG. “The Alfa Laval technology developed thus far and the experience gained in the testing process will be invaluable when testing other zero-carbon alternatives such as ammonia and other hydrogen mixtures”, he said.

Encouragingly, progress is being made. Woodward L’Orange has developed a family of high-pressure dual-fuel injectors for high- and medium-speed gas and diesel-powered engines that, the company believes, reduces methane slip to “an absolute minimum”. As Mr Senghaas told the Cimac conference in a paper called New injector family for high-pressure gas and low-caloric liquid fuels, Woodward L’Orange has high hopes for the technology in the post-2020 world: “The proposed injector family is [designed] to inject several low-energy or gaseous fuels. It is ready to provide customers [with] a broad range of new combustion options.”

But does methane slip matter that much? Most of the debate about methane slip refers to LNG-fuelled vessels, but advocates argue that LNG is only a bridge – or interim – fuel on the way to a zero-emissions future and that methane slip is a small price to pay for its other virtues. Unsurprisingly, the general manager of the lobby group Society for Gas as a Marine Fuel, Mark Bell, agrees with this assessment: “It would be totally unfair to hang LNG on methane slip.”

The operative issue though is how much methane slip is there? According to a study compiled by the Society for Gas as a Marine Fuel and Sea/LNG entitled Life Cycle GHG Emission Study on the Use of LNG as a Marine Fuel released in April 2019, there is not a lot. Slow-speed dual-fuel engines showed methane emissions of 0.14 grams per kwh, which adds up to less than 1% of the total well-to-wake GHG emissions of the engine.

However, the numbers for the low-pressure injection system and combustion of Otto-cycle engines are higher. The dual-fuel power unit released methane emissions of 2.1 grams per kwh, adding up to 11% of total GHG emission from well-to-wake. To confuse the issue further, another paper presented at Cimac entitled Methane Slip Summarised: Lab v. Field Data suggested that methane slip may be higher in sea-going rather than test-bed conditions.

Meantime, what is the likelihood of the emergence of fuels that do not release any GHG?

As Bureau Veritas points out, biofuels offer a highly desirable carbon-neutral solution that is increasingly available as a marine fuel, although in small quantities. In fact, biofuels are in such short supply that not even kerosene-burning airlines or diesel-fuelled trucks can get enough of them, let alone shipping companies. However, volumes are growing; Mediterranean Shipping Company announced in mid-December that it is following up successful trials by loading up its cruise ships with 30% blends from bunkers in Rotterdam.

Although highly attractive, synthetic alternatives lie far over the horizon. Volumes of synthetic methane and bio-methane are extremely small and expensive. Perhaps closer, although not by much is ammonia, a ‘clean’ fuel based on one of the world’s most widely used chemicals.

Between now and 2030, when IMO’s tougher decarbonisation regulations will apply, the race is on to produce cleaner fuels in big volumes. As Wärtsilä’s director for marine in East Asia and China, Osten Lindell pointed out ahead of early December’s Marintec China 2019: “The single biggest contributor to lowering emissions is fuel choice.” Citing bio-LNG, synthetic LNG, ammonia and hydrogen as examples, he added: “It is clear that the industry needs to adopt greener fuels.”

Meantime, engine-builders are pulling out all the stops in the fight to reduce methane slip before regulators vote to get tougher.

The combustion engine’s problem child

Methane is slipping everywhere, not just from ships’ engines. It is escaping from stationary gas-powered industrial engines in wastewater treatment plants, for example, as well as from internal combustion engines in all kinds of vehicles.

“The problem child in engine exhaust emissions is total hydrocarbons (THC), consisting substantially of methane,” explains Caterpillar’s Heinrich Baas in a paper released in July 2019 entitled Emission Reduction for Combined Heat and Power Plants. Scientifically speaking, THC represent methane that has passed through the combustion process unburned and then into the exhaust gas flow. “This is a thorn in the side of development engineers because ideally this methane should burn in the combustion chamber, further increasing efficiency.”

Over the years, the amount of slip has been reduced by engineering modifications, for instance to the geometry of the combustion chamber. “However, from an environmental perspective this is not good enough as the GHG potential of methane is about 23 times that of CO2,” Mr. Baas notes.

In Europe alone, Caterpillar is engaged in a range of intensive projects the purpose of which is to find catalysts that slash methane losses, but so far these have not survived in industrial applications. “This area needs further research,” he notes.